Introduction to Belt Drive

Belt Drive

Belts

A belt is a loop of highly flexible material (usually reinforced rubber

or polymer) that is used to mechanically link rotating shafts. Belts are looped

over pulleys (also called sheaves) and they can be used for connecting several

shafts together, such as seen in the figure. The major disadvantage of belts is

that they have shorter life than gears, shafts, etc.(they usually fail due to

wear or creep).

|

| Belt Drive |

Types of Belt - Based on cross section

· Flat Belt

· V-Belt or Wedge Belt

· Timing or Toothed Belt

· Round Belt

Types of Belt Drives

· Open belt drive

· Cross belt drive

· Quarter turn drive

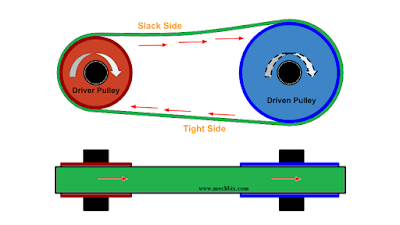

Open belt drives

|

| Open belt drive |

An open belt drive is used to rotate the driven pulley in the same direction of driving pulley. In the motion of belt drive, power transmission results make one side of pulley more tightened compared to the other side. In horizontal drives, tightened side is always kept on the lower side of two pulleys because the sag of the upper side slightly increases the angle of folding of the belt on the two pulleys.

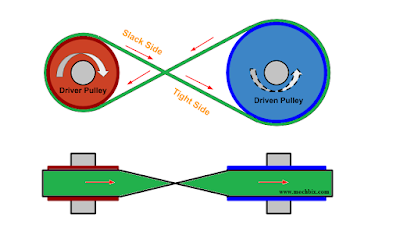

Cross belt drives

A cross belt drive is used to rotate driven pulley in the opposite direction of driving pulley. Higher the value of wrap enables more power can be transmitted than an open belt drive. However, bending and wear of the belt are important concerns.

|

| Cross Belt Drive |

Materials used for belts

Since belt drives are friction drives, belts are made from materials which have high co-efficient of friction. Since the belts are made of different materials, the coefficient of friction also varies. Hence co-efficient of friction decides how much power is transferred. Some of the commonly used belt materials are listed below.

Leather belt

Nylon-Core belt

Rubber belt

Cotton and Canvas belt

Balata Belting

Rubber on fabric belt

Law of Belting

The law of belting states that the centerline of the belt when it approaches the pulley must lie in the mid plane of that pulley which should be perpendicular to the axis of the pulley. Otherwise the belt will run off the pulley.

Crowning of pulleys

Pulleys are provided a slight conical shapes (or) convex shapes in their rims surface in order to prevent the belt from running off the pulley due centrifugal force. This is known as crowning of pulley.

Usually the crowning height t may be 1/96 of pulley face width.

Factors should be considered during the selection of a belt drive

a) Amount of power to be transmitted

b) Peripheral and angular speeds

c) Speed ratio

d) Efficiency

e) Centre distance between shafts

f) Space available

g) Working environment.

Advantages of belt drives

· Belt drives are simple are economical.

· They don’t need parallel shafts.

· Belts drives are provided with overload and jam protection.

· Noise and vibration are damped out. Machinery life is increased because load fluctuations are shock-absorbed.

· They are lubrication-free. They require less maintenance cost.

· Belt drives are highly efficient in use (up to 98%, usually 95%).

· They are very economical when the distance between shafts is very large.

Disadvantages of belt drives

· In Belt drives, angular velocity ratio is not necessarily constant or equal to the ratio of pulley diameters, because of slipping and stretching.

· Heat buildup occurs. Speed is limited to usually 35 meters per second. Power transmission is limited to 370 kilowatts.

· Operating temperatures are usually restricted to –35 to 85°C.

· Some adjustment of center distance or use of an idler pulley is necessary for wearing and stretching of belt drive compensation.